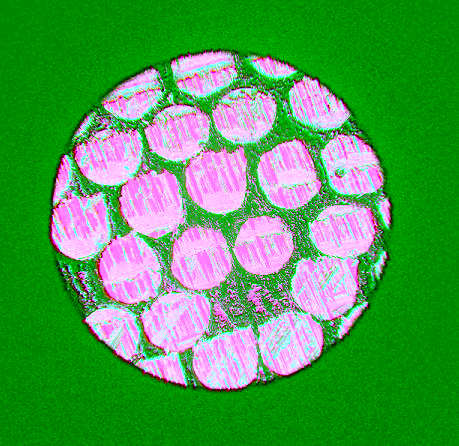

UV Current Dip Impregnation

For the best impregnation results, fastest processing times and reduced process costs UV Current Dip is leading the way for electric motor manufacturing

- Very high levels of slot fill

- Partial discharge testing proves the effectiveness of the application

- Quick processing times

- Low environmental impact

- Low drainage losses

- Large variety of machinery available for your application

- Reduced manufacturing cost

- Better electric motor longevity