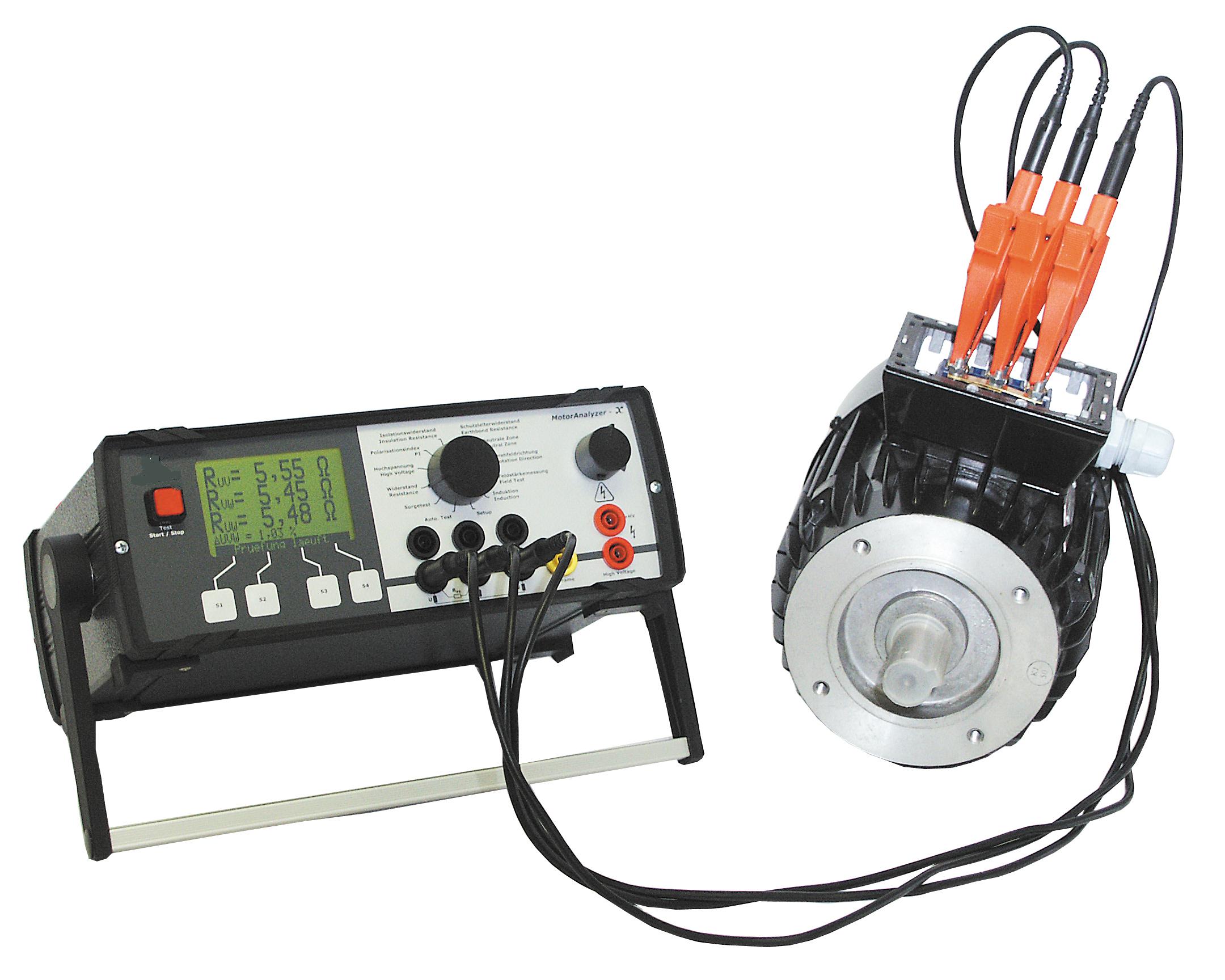

Motatest 1 Multi-Function Tester for Electric Motors

The Motatest 1 is an all-purpose tester for testing electric motors and products with windings. It combines ten different test methods in one user-friendly and very mobile device. The combination of the test methods, its very compact desgin as well as the battery operation makes the Motatest an ideal tool for on-site service applications - especially at very difficult installation situations.

For testing a three-phase motor the three winding connections as well as the motor frame are connecetd to the tester. Afterwards the Motatest analyses fully automatically the motor via surge voltage and resistance test. After this the motor is also tested with a high-voltage test to evaluate the quality of the motor fast and clearly.

The following testing methods are integrated into the terster:

- turn-to-turn by probe,

- surge test. 12V

- high-voltage test DC, 0-4000V max 3mA

- polarization index,

- insulation resistance 50-6000V, 1M-100GOhm

- PE-resistance test, 200mA DC 0-1 Ohm

- neutral-zone test for DC motors,

- sense of rotation test of the rotary field,

- field strength distribution test and

- resistance test. 0,001-499KOhm